HKUST Researchers Develop the World’s Strongest Polymer Nanomembrane

Showing Potential for Multiple Biomedical and Environmental Applications

Researchers from the Hong Kong University of Science and Technology (HKUST) have developed an ultrathin polymer nanofilm, which is not only 25 times stronger1 than stainless steel with the same mass, but is also extremely transparent, gas-permeable and water-proof with adjustable porous properties, making it suitable for use as wearable devices, medical protection, desalination, electronics, solar cells and many other cutting-edge technologies.

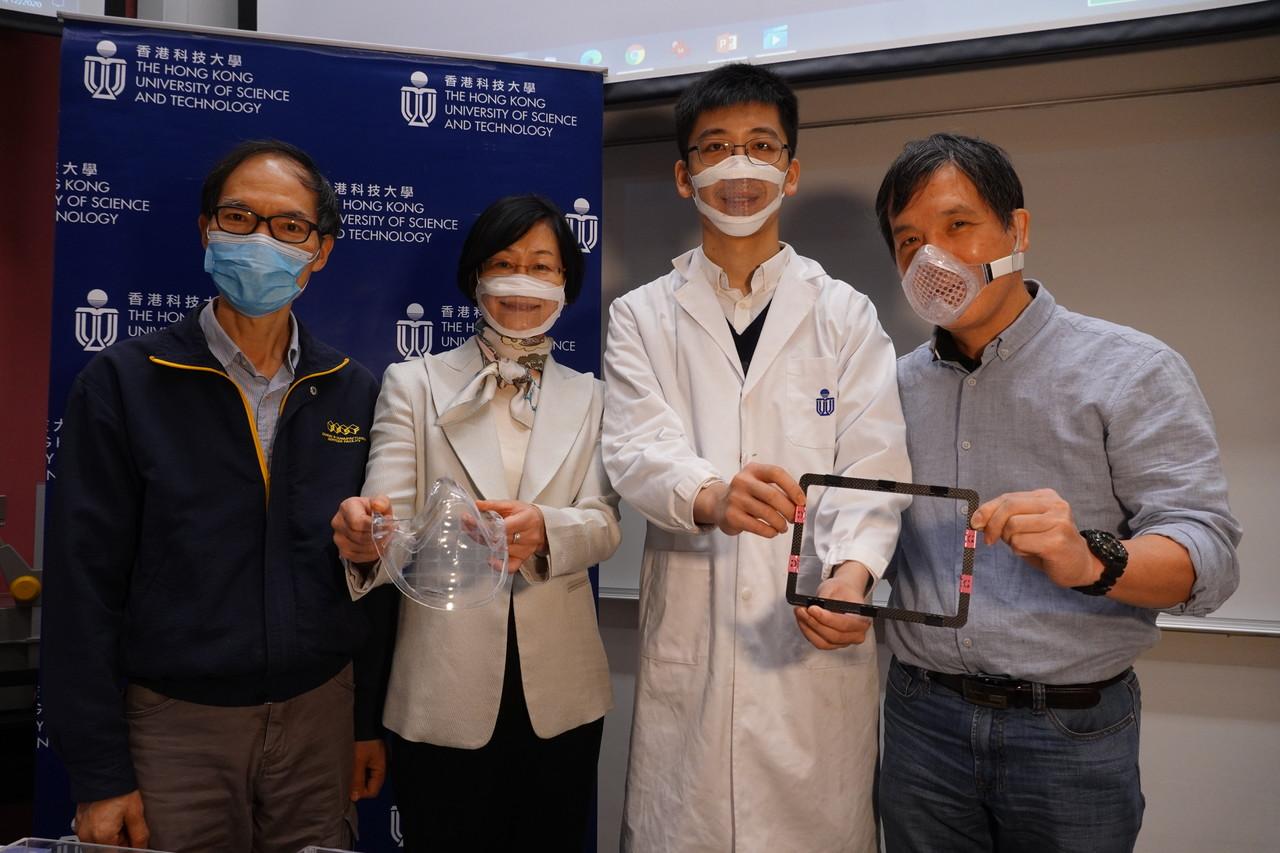

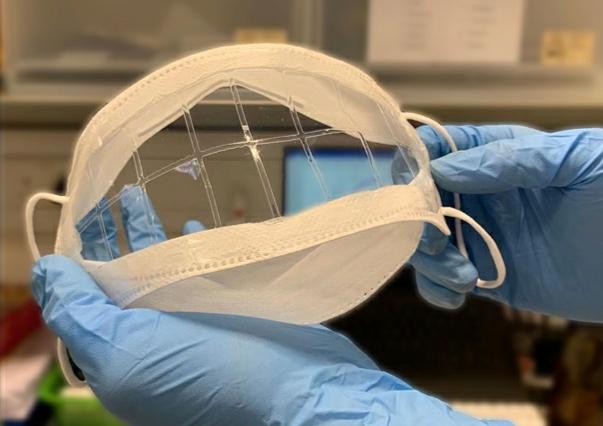

Since the onset of the Covid-19 pandemic, the team led by Prof. Ping GAO, Professor of Chemical and Biological Engineering and Acting Head of the Advanced Materials Thrust at HKUST(GZ), has been studying how to build a transparent and breathable face mask with their novel advanced material. After months of efforts the team has finally produced a prototype with a 99 per cent filtration efficiency for virus, bacteria and particulate matters under tests in line with NIOSH NaCI (N95 respirator testing standard)2 .

“This novel material has many potential, but since the pandemic struck, we focus on turning our nanofilm into a face mask that is not only transparent and breathable, but is also highly efficient against virus and bacteria, as we haven’t yet seen one in the market which bears all three properties,” said Prof. Gao. “While common opaque surgical masks can protect the wearer from infection, they are not convenient for the hearing-impaired people who need to communicate via lip reading and facial language; or teachers, child carers or performers who rely heavily on facial expressions in teaching, nurturing or performance.”

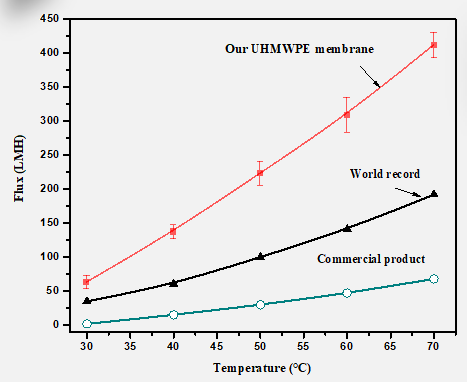

Apart from face mask, the team has also filed six other patents for the material’s application in other areas. The nanofilm’s adjustable porous property, for example, has made it the world’s most potent polymeric membrane for membrane distillation desalination so far, with an efficiency 10 times higher than existing products in the market and almost three times above world record.

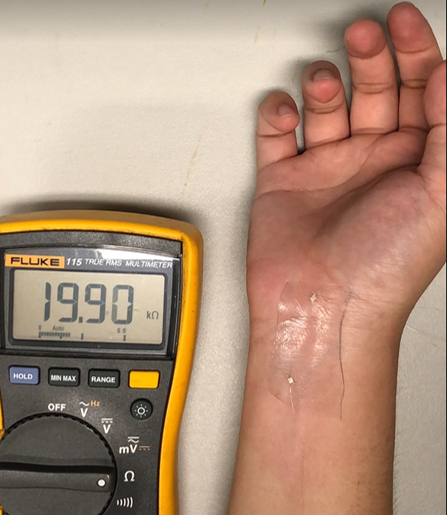

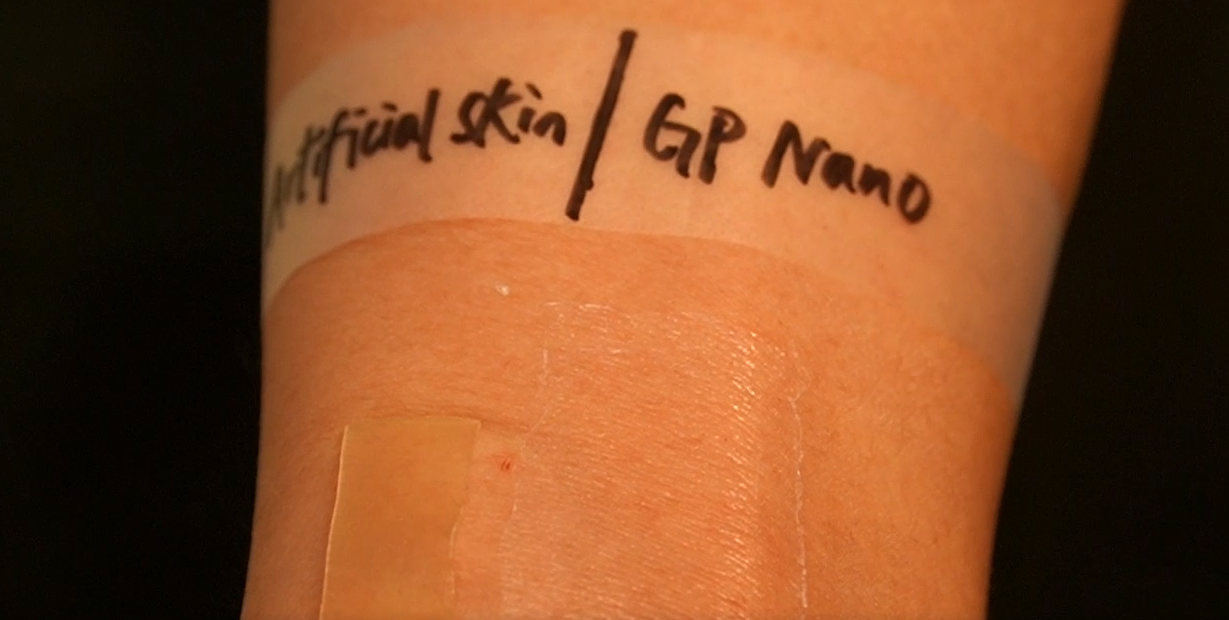

Meanwhile, its conformity, antibacterial, transparent yet strong properties has also made it an ideal material for various biomedical causes, including a new generation of wound dressing which require no daily replacement and allows direct application of medicine.

“Wound dressing made with this nanofilm is particularly useful for patients who suffer large-scale burns,” said Prof Gao. “It acts like a temporary skin to the burn victim, doctors can apply medicine directly over the film, which would filter through to the wound beneath. As the film is completely water-proof, wearers can even take a shower without fearing of wetting the wound.”

The material also makes a much better motion sensor for people, it can also be adopted for the design of robotic motions. Apart from biomedical and environmental use, the nanofilm can also be applied to electrical appliances, such as nanovibrational speaker with higher resolution of audio output or ultrathin batteries and high-energy density capacitors.

This nanofilm developed by the team – measuring just 20 nanometers or less than one thousandth the thickness of a hair strand - is made from the ultra-high-molecular-weight polyethylene (UHMWPE) – a light-weight material used in bullet-proof vest. It was very difficult to reduce UHMWPE to nanoscale as the powder-like material breaks at a certain level under the conventional methodology which stretches it in opposite directions to change the intrinsic orientation of the disordered and entangled polymeric chain.

But Prof. Gao found a way to detangle the polymer chains. Similar to applying conditioner to smoothen the hair, Prof Gao’s team put UHMWPE into a lubricant and transform the material into a gel form, successfully enhancing its drawability while preventing the polymer chains from knotting. The team is thus able to rearrange the polymer chains into a topologically triangulated stable structure – a structure where some of the strongest material built upon.

Prof. Gao’s PhD student GU Qiao as well as CHEUNG Shu Kwan and Walter LEE from Design and Manufacturing Services Facility of HKUST have helped designing the transparent face mask.